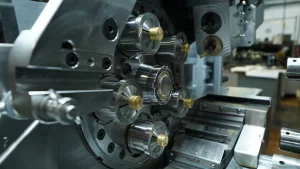

In the realm of home construction projects, the role of advanced metalworking machinery is crucial. Efficiently crafting top-notch components is key to project success. Despite this, many builders still rely on outdated tools. Integrating comprehensive metalworking machinery can address common issues like delays, cost overruns, and quality control. What are the advantages of this technology and how can it seamlessly fit into existing workflows?

Key Takeaways

- Comprehensive Metalworking Machinery enhances productivity and output quality, streamlining production processes in home-building projects.

- Strategic integration of all-inclusive machinery alleviates common obstacles, including delays, budget overruns, and quality control issues.

• Advanced machinery facilitates automation, reducing manual labor and the risk of errors, while increasing precision and efficiency. - Precision machinery minimizes material waste, reduces rework, and saves costs by ensuring projects stay within budget constraints.

- Investing in comprehensive machinery leads to long-term cost savings, increased efficiency, and reduced lead times in home-building projects.

Challenges in Home Building Projects

In numerous home-building projects, a variety of challenges arise, hindering the successful completion of the project, and some of these obstacles can be effectively addressed by the strategic integration of extensive All-inclusive Metalworking Machinery. Delays, budget overruns, and quality control issues are common hurdles. Effective project management and creative solutions, such as utilizing All-inclusive Metalworking Machinery, can alleviate these challenges.

Frequently Asked Questions

Can Comprehensive Metalworking Machinery Be Used for Small-Scale Projects?

Yes, versatile metalworking machinery can be scaled down for small-scale projects, offering precision and efficiency, even in compact spaces, making it a valuable investment for home builders and DIY enthusiasts.

What Safety Features Should I Look for in Comprehensive Metalworking Machinery?

When selecting extensive metalworking machinery, prioritize safety features such as emergency stop buttons, safety interlocks, and protective guarding to prevent accidents and guarantee a safe working environment for operators and bystanders.

How Does Comprehensive Metalworking Machinery Improve Project Timelines?

‘Comprehensive metal fabrication equipment streamlines home building projects by optimizing manufacturing, cutting, and assembly processes, resulting in reduced project timelines and increased efficiency, allowing builders to complete projects faster and meet strict deadlines.’

Can I Customize Comprehensive Metalworking Machinery for Specific Projects?

Yes, all-encompassing metalworking machinery can be customized to meet specific project requirements, allowing for tailored solutions that optimize efficiency, reduce costs, and improve overall project outcomes.

What Kind of Maintenance Is Required for Comprehensive Metalworking Machinery?

‘Regular maintenance for all-inclusive metalworking machinery involves lubricating moving parts, cleaning debris, and inspecting for wear and tear to guarantee top performance, extending equipment lifespan, and minimizing downtime in home building projects.’

Conclusion

The integration of advanced metalworking machinery in home building projects yields significant benefits. By optimizing resource utilization, reducing manual labor, and improving precision, builders can alleviate delays and budget overruns. The automation of processes improves operational efficiency, leading to successful project outcomes and cost savings. Ultimately, the incorporation of advanced machinery is essential for achieving high-quality output and streamlining construction processes.

You May Also Like: